WHY TANABE WILLTEC

As expert of separation and drying,

TANABE is devoted to provide the best solution for customers' needs.

Why TANABE is your choice

We are committed to provide most suitable solution for customers` need by utilize our expert and experience.

-

01

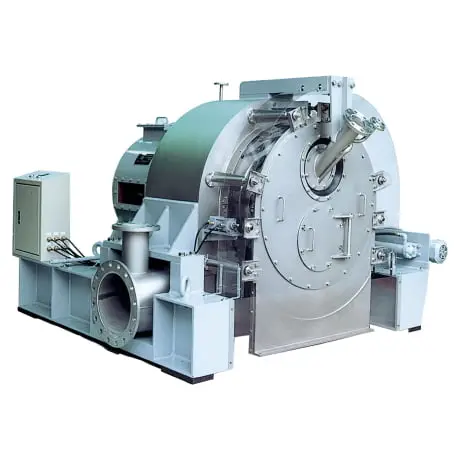

01Our commitment to technology and craftsmanship for over 100 years since the foundation.

"As the pioneering centrifuge maker, we have refined our technology over many years by responding to customers different needs. We always move forward to develop new products which match the needs of times by delivering more than 10,000 sets of centrifuges."

-

02

02Top market share , oversea business experience of over 50 years

Owning a wide range of product variations, we keeps proposing and deliver products that match the needs of all sectors such as automotive, semiconductor, energy, pharmaceutical, food, recycling, and aerospace.

-

Application examples

-

Intre-machinery cleaning model

GMP-compliant DEVO model is developed in order to respond to a request from one electronic equipment maker, who wishes to conductor intre-machinery washing after every batch. (immersion washing)

Application examples -

Continuous Decone type

De-cone, which can perform continuous filtration separation and have a high dewatering efficiency, is developed with one resin maker, who want to dewatering the resin beads in large scale.

Product lines -

Solid rinse decanter

CR type decanter, which can perform solid rinse at the same time, is developed after R&D with one organic compound customer, who needs large scale production and solid washing at the same time.

Product lines -

Filter dryer for full solid discharge

Gas knife agitator is developed for remaining solid discharge to answer the needs from one pharmaceutical intermediates customer who wanted to discharge all of the remaining solid.

Product lines

Steps from inquiry to final centrifuge delivery

-

01

Plan

-

02

Specification discussion

Your current process information and capacity will be needed to decide the general test plan.

-

03

Lab test

Lab test will be done to check if centrifugal separation can be achieved or not ( about 200ml to 1L of sample will be needed for lab test )

-

04

Sample test

Actual test will be performed by test machine. of Couse, sending the test to your place is also a good choice as it can be incorporated into your current processing line. Scale up (model selection) will be done basing on the sample tests.

-

05

Model selection

Most suitable model will be proposed for your desired capacity.

Please feel free to contact us for any inquiry.